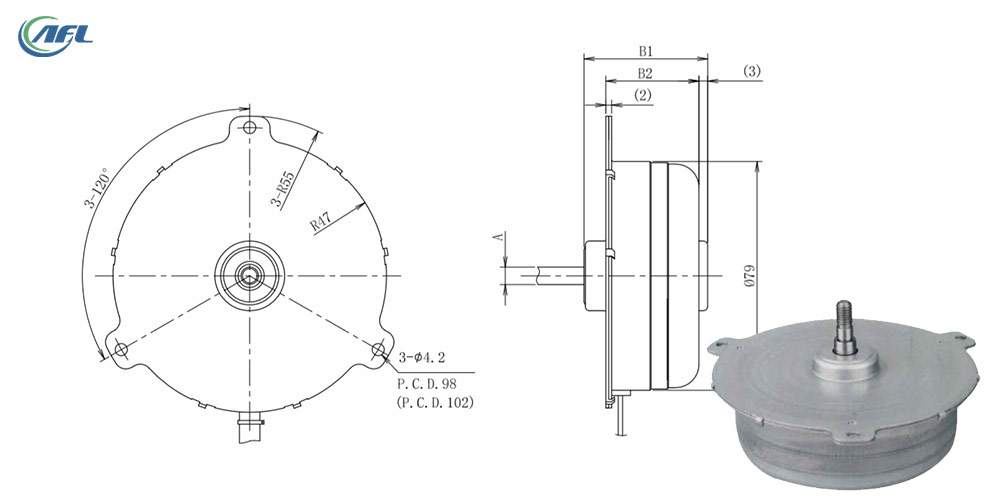

Product Types: Internal Rotor Motor

Nominal Voltage : DC310V

Tach Output : 12Pulse/R

Speed Control : 0~6.5VDC/PWM

Insulation Class : B

Approvals : CCC CE

INDEPENDENT

PRODUCTION

LEADING R&D

TECHNOLOGY

COOPERATIVE

PARTNER

Product Types: Internal Rotor Motor

Nominal Voltage : DC310V

Tach Output : 12Pulse/R

Speed Control : 0~6.5VDC/PWM

Insulation Class : B

Approvals : CCC CE

Product Types: Internal Rotor Motor

Nominal Voltage : DC310V

Tach Output : 12Pulse/R

Speed Control : 0~6.5VDC/PWM

Insulation Class : B

Approvals : CCC CE

What is the Internal rotor motors

Internal rotor motors are a type of electric motor that uses a rotor that is enclosed within the motor housing. They are often used in applications where high speed and torque are required, such as in electric aircraft or electric power tools. Internal rotor motors are also frequently used in industrial applications, where they offer high reliability and low noise levels.

Internal rotor motors provide power for a variety of devices, including medical equipment and toys. These motors are typically smaller and more compact than traditional electric motors, which makes them ideal for use in devices that need to be portable. They are also less expensive to produce, making them a popular choice among manufacturers.

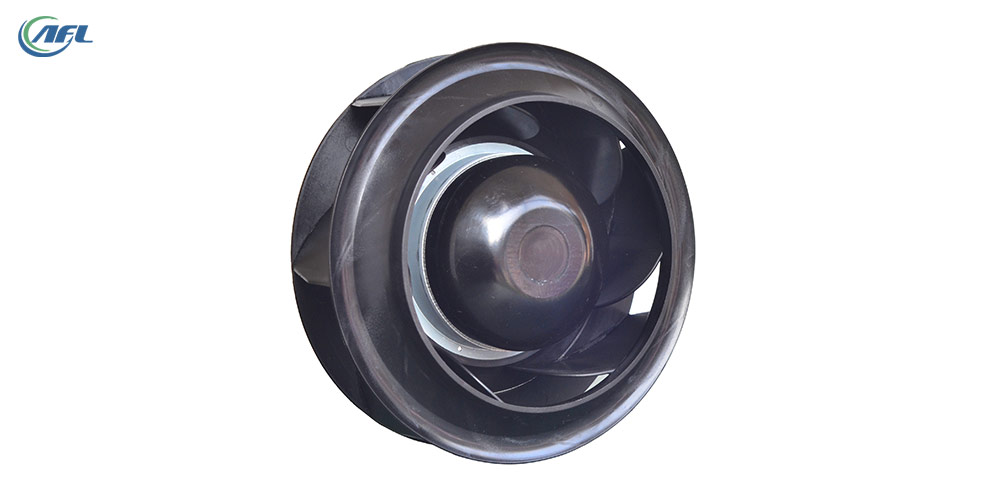

A centrifugal fan is a device used to move air. The internal rotor motor is used in many electronic devices because it has a high level of efficiency. This type of motor is also used in centrifugal fans because it is efficient and durable.

A centrifugal fan is a popular device for providing ventilation in enclosed spaces. The internal rotor motor is a type of fan that uses a spinning disk to create airflow. This type of motor is often used in devices that need to be portable, like laptop computers.

Internal rotor motor is a quieter, more efficient design that can significantly reduce noise levels in your home or office.

This motor features a high speed and low noise design that makes it ideal for use in quiet areas like bedrooms or offices.

Its compact design means it can be easily installed without disrupting the surrounding area.

Internal rotor motors are also environmentally friendly, making them a great choice for those looking to reduce their carbon footprint.

Finally, internal rotor motors come with a limited lifetime warranty, ensuring that you're always guaranteed quality and performance.

We know that there are many types of fans, of which the external rotor axial flow fan is the main one. Generally, there are two types of fans, one is an external rotor fan and the other is an internal rotor fan. So what is the difference between an external rotor axial fan and an internal rotor fan? Let’s take a look.

The external rotor fan adopts the advanced structure and reasonable aerodynamic design that the external rotor motor directly drives the impeller, and has the characteristics of high efficiency, low noise, light weight, compact structure, convenient installation and maintenance.

Internal rotor fan is an assembly spindle or motor composed of iron core and coil. After power on, AC internal rotor fan generates a magnetic field through the starting copper block in the motor to work; DC fan uses Hall IC to drive the fan to generate a magnetic field and rotate. Generally, DC fans have an inner rotor structure, AC fans are mostly inner rotor blades, and outer rotor blades are basically metal iron blades.

The advantages of AC inner rotor fan blade are that the blade is light, the motor is easy to produce and assemble, and the cost is low. The rotor fan blade fan in DC generally has a high speed and is easy to be protected. And the air volume of the rotor fan in the AC can be much larger, and it can be made into energy-saving control products. The disadvantage is that the AC inner rotor fan is easy to damage the motor due to unstable voltage and has a short service life. In addition, the motor temperature rises, the speed is low, and the power consumption is large.

AC outer rotor fan blades are basically connected with spindles and fan blades (iron blades or plastic blades). The motor can be made into a fully enclosed honeycomb structure, and it can run quickly by starting the capacitor. Its advantage is: AC fans of major international brands have more external rotor structures. Because of its low power consumption, high speed, and work efficiency much higher than that of the inner rotor. The metal fan blade has large inertia and the fan is resistant to high and low temperature environments. The motor can be directly dust-proof and moisture-proof, and can even be made into an IP56 protection level. It is not easy to damage and has a long service life. The disadvantage is that the cost is higher than the internal rotor fan.

The characteristic of centrifugal fan is that the pressure rises quickly, which mainly depends on the width of the impeller, the air performance and the appropriate large flow rate. The air flow conforms to the phase law. Under the same pressure and constant flow rate, the flow changes linearly with the increase of the width of the impeller. Usually it needs to be equipped with a rotating chamber (volute). The rotating chamber is generally made of aluminum, galvanized sheet or plastic.

Through the introduction of "the difference between external rotor fans and internal rotor fans" above, we know that there are actually many differences between external rotor axial fans and internal rotor fans. Because there are so many differences between the external rotor axial fan and the internal rotor fan, these two types of fans will focus on different areas. But these two kinds of fans are very important to us, we must understand.

AFL is a leading company that focuses on Internal Rotor Motor in China. We solemnly promise to provide your products with excellent quality, reasonable prices and the highest cost performance.Inner rotor factory manufacturers are an important part of the industrial sector, providing essential components for a wide range of applications. Their expertise in producing custom-made parts for various industries is invaluable and often times overlooked. As technology advances, the need to produce more complex components has grown, requiring innovative solutions from these factories. Inner rotor factories have risen to the challenge by using cutting-edge materials and processes to create intricate parts that serve modern needs.

In addition to inner rotor motors we also offer Backward Centrifugal Fans, Forward Centrifugal Fans, Single Inlet Forward Centrifugal Fans, Double Inlet Forward Inclined Centrifugal Fans, Axial Fans and more.

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Internal Rotor Motor, Dc Motor. We warmly welcome clients, enterprise associations and mates from all over the globe to speak to us and find cooperation for mutual rewards. The product will supply to all over the world, such as Europe, America, Australia, Denmark, Mongolia, Argentina, New Orleans. To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

You can follow the link to see our facebook homepage.

Click on the link to go to our LinkedIn homepage.

You can also click the link below to enter our YouTube homepage to view.

Add: No. 10, He Ping Road, Zhou Wang Miao Town, Hai Ning City, Zhejiang Province.

Phone: +86-573-87539706

E-mail: yx01@hzafl.com